Table of Contents

- Cultural Value Of Basmati Rice

- Process Of Growing Rice At Home

- Manufacturing Process Of Indian Basmati Rice

- Milling Process Step By Step

- Protection Of Plants From Pest And Diseases

- Conclusion

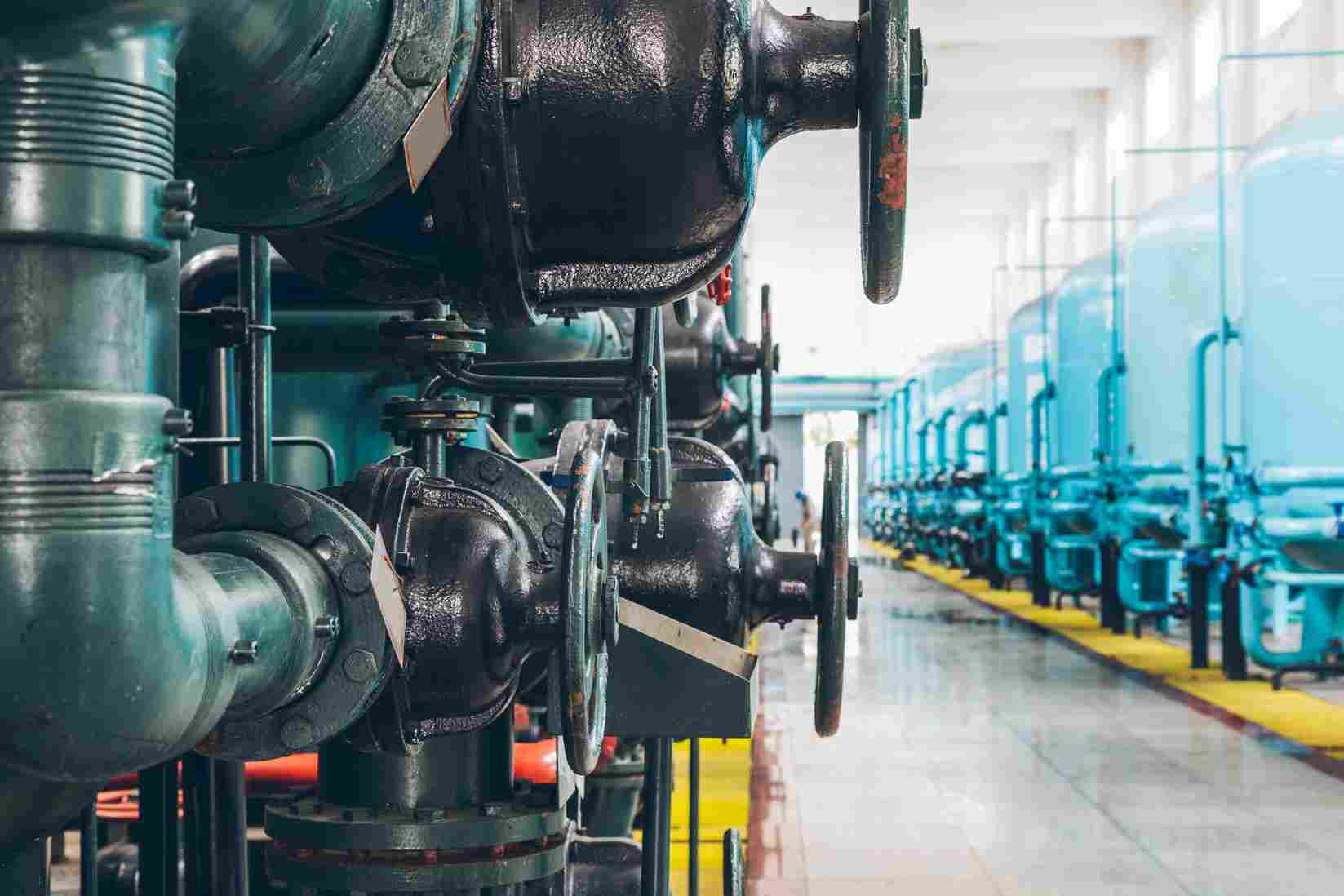

Milling process is a significant step after the cultivation of rice or any crop. The aim of machinery used in the milling process is to achieve a fine quality grain by removing the bran and husks. Therefore, it became an edible item efficiently.

Basmati rice exporters of India are the key factor to increase the ratio of exporting in the global market. This type of rice has a long history and is believed to be the oldest meal in humankind’s diet.

According to the research by Archaeologists, Indian basmati rice has its footprints long before 5000 BC. Also, some historians have studied that it has relations with China.

China has done the rice ceremonies yearly in about 2300 BC. Basmati rice has faced many weather changes but survived only some.

Cultural Value Of Basmati Rice

In several countries, rice is majorly served on auspicious days. It holds a huge respect in comparison to other meals. Even in Indonesia and Japan, this grain has their own gods respectively.

In South Africa, they celebrate a fully dedicated day to rice crops with an emotion of new year festivities.

In other Asian countries, rice is presumed as a thread or pure connection between the Earth and Heaven.

Indians believed the basmati rice as a supreme fertility. This belief led the grain to achieve a valuable importance in rituals as well. It is well connected to the ritual performed in weddings during a vidai for centuries, of throwing rice.

Process Of Growing Rice At Home

Indian basmati rice comes in many varieties and each variant has a different texture and size.

It can be found in all lengths such as: long grains, medium sized or in broken types. Rice is not so difficult to cultivate in your backyards. It can easily be produced in buckets, in gardens etc by using only some important ingredients.

The required things in correct amount:

- Soil, perfectly fertilized in exact amounts.

- Moisture, in perfect amount,

- Water for irrigation and other useful nutrients,

Proper time and care to protect the production and to enhance the quality of rice. Mostly, this crop is cultivated in the rainy season for short, long or medium grains.

After the maturing of grains, the water must be drained out from the pot or place where it is developing. Then, harvest your own cultivated grain. But stil, a milling process is mandatory as the harvest grain is not edible until it is processed.

Once the milling process is done, it becomes better to consume easily.

This was an overview about how this process works to provide an instant image of cultivated rice. Let us now discuss the whole process of manufacturing the rice by the Basmati rice exporters efficiently.

Manufacturing Process Of Indian Basmati Rice

- Rice Harvesting – Initially, it is the first step after completing the perfect cultivation of rice. In this stage, millers do the harvesting by the use of machines or by hands. It is dependable on the size and amount of grains.

However, the traditional ways are not appropriated nowadays because it deteriorates the quality. Those ways were; drying fields and piling etc. The harvesting of crops includes many steps which are as follows:-

i) Reaping, ii) Threshing, iii) Cleaning, iv) Hauling, v) Stacking, vi) Packaging.

- Drying of rice – It is the second step, in which the harvested rice needs to be dried fully and diminished the moisture in it. Drying up the rice can also be done naturally by sunshine or artificial heat. It concludes process as follow:-

i) Removal of moisture, ii) Monitoring the drying process at times, iii) Increasing the temperature of drying, if using the artificial heat, iv) Uniform drying and last the tempering.

- Hulling – In this step, the dust and hull are removed from the rice. In this scenario, hulling is dependable on the regions in which the rice has been produced. It can be done by using a machine or by hands. Removing stones in the rice is the key motive to attain the brown basmati rice.

- Milling – In order to achieve the white fine basmati rice, milling is the process in which the rice has to go through. The bran layers outside the brown rice need to be removed by the milling process. At the end, we are able to attain the white grain, Indian basmati rice.

It is a long process as per the Indian rice supplier, also it can be done in a single process or by taking two steps and by multiple steps as well.

Milling Process Step By Step

- In a single step, only the husking and bran removal process is carried upon altogether, in a single go.

- In a two step process, it requires the husking and bran layer removal process then the separation step.

- Multiple steps have various steps to follow to attain a fine enriching rice grain. Those steps are as follows:-

> There are various machinery used during the milling process in order to accomplish the white basmati rice from the brown rice;

i) The first and foremost process in milling is a pre-cleaning of rice by using a machine, known as paddy cleaner. In this, the larger size of stones, dust or any heavy particles are removed respectively.

ii) The second step follows a process of de-husking and dehulling. Basically, it is important to remove the husk or tiny particles in grains. The smaller size stones are removed in this particularly which the pre-cleaner is unable to remove.

iii) Here, the separation happens between the brown rice and unhusked paddy grains. It is generally known as paddy separation.

iv) Removing the bran layer from brown rice then makes the rice white by using a whitener, called a whitening process. Followed by this, the rice is polished to improve the appearance of it and enrich the texture of rice. Hence, it became the Indian White Basmati rice through the Whitening and polishing process.

v) Then, this step is the weighing and packaging of the rice grains. It is important to export the item through the Indian basmati rice exporters and rice suppliers. It is prepared as per the requirement of the customer then gets ready to transport the item.

vi) In this final step, to enhance the aroma and the value of nutrients, the process of parboiling is to be done. Parboiling helps in improving the quality and the royal aroma of grain altogether.

The final step is mandatory because it recovers all the nutrients and healthy particles which get hidden during the milling process. So, it is important to redeem those fine nutrients, minerals etc.

Above, we have discussed the milling process along with the manufacturing process. As, milling process of Indian basmati rice is a part of the manufacturing of it by the rice suppliers and rice exporters.

Protection Of Plants From Pest And Diseases

There is an optimum method to fight with the disease and pests. While growing the rice, some steps are intended to consider in your process as below mentioned-

- The cleaning of the ground is the foremost essential activity. The cleany ground is far away from catching the pests.Use the cleaned tools between the processes and climate changes.

- The use of fine quality and expert level of grains to avoid the blemished seeds.

- Try not to use excess fertilizations. It causes unwanted germs and bacteria in plants.

- Make a suitable storage for grains at earliest. Because, in some cases, the grains are kept in tidy and moisturized containers which ultimately cause pests.

In order to keep your rice grains pest-free and disease free, these are the basic things to keep in mind.

Conclusion

We believe, by adhering to these recommendations above, the general information will lead you to grow qualitative grains. In this modern era, there are various machines that are used by the rice millers.

Indian basmati rice milling is an extremely important process in the global trade market to export to other countries. By the passing time, there is a growth in ways of milling to accomplish the finest quality grain, full of nutrients.

The milling process is done to determine the rough rice into the fine quality with an amazing texture. It basically enhances the grain quality and recovers all the important nutrients which is the demand of a human body.